How do you deal with the resin left in the vat after each print? Do you directly pour it back into the resin bottle? Please don't do that, because not only will it be the main reason for your next print failure, but also ruin the fragile FEP film.

In this article, you can see two multifunctional funnel 3D models designed by Anycubic, and how to use them to do with the rest of the resin after print.

Download now: Anycubic Resin Funnel STL files

How to Filter Your Resin with Anycubic Funnel 3D Models

Tools You Need

- Printed Funnel

- Paper Strainer

- Clean Gloves

- Paper Towels

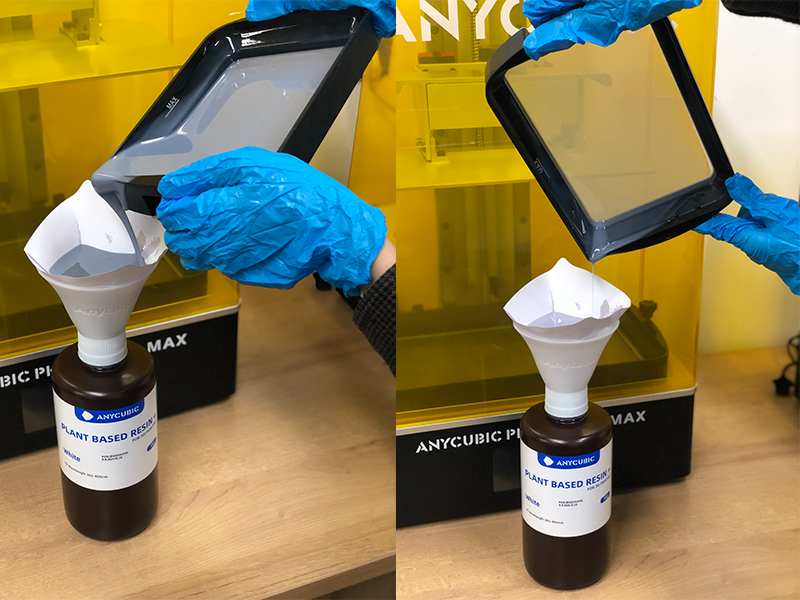

Step 1: Wear clean gloves, and cap the funnel tightly over the resin bottle.

Step 2: Put the filter paper on the funnel.

Step 3: Pour and scrape off all the resin from the tank.

Step 4: Wipe the funnel with paper towels.

(step1)

(step2-step3)

Caution: Before throwing away these tools, such as paper towels, funnels, strainers, gloves or anything that got liquid resin, please put them out in the sun or Anycubic Wash & Cure Machine for a full UV cure until they are completely dry.

Why We Recommend Anycubic Funnel 3D Models

1. Avoid leakage and a mess — the pointed diversion port on the top and the cap on the bottom keep the resin bottle clean when pouring resin, moreover the funnel with a bottom cap 100% fits both Anycubic 500g&1000g Resin Bottles.

2. Easy to use — the funnel acts as a sturdy base, holding the paper strainer inside to prevent spilling or tipping over, while effectively filtering small pieces of cured resin hidden in the vat.

3. Save cost — save about $1, each time uncured resin is filtered from the tank for reuse.